Renewable energy is by its very nature intermittent. Winds blow at different speeds on different days and daylight hours dictate how much solar energy can be generated. This is why electrical energy storage systems are so important for the energy transition. Here in Finland, we could produce lots of solar energy during the summer months and store that for use in winter. Batteries aren’t suitable for this sort of storage, since they store smaller amounts of energy for a shorter period. Electricity produced by renewable energy technologies can be stored for a long time in large quantities in chemical form by producing green hydrogen and other electrofuels using technologies such as reversible fuel cells.

A fuel cell is an electrochemical device that converts hydrogen in its chemical form into electricity. It contains no moving parts, and its waste material is water. Unlike a combustion engine, which burns fuel to generate power, fuel cells can work ‘in reverse’ meaning, they can convert electricity back into the chemical hydrogen form. However, an existing limitation of fuel cell technologies are their durability and production, as they require critical materials to function.

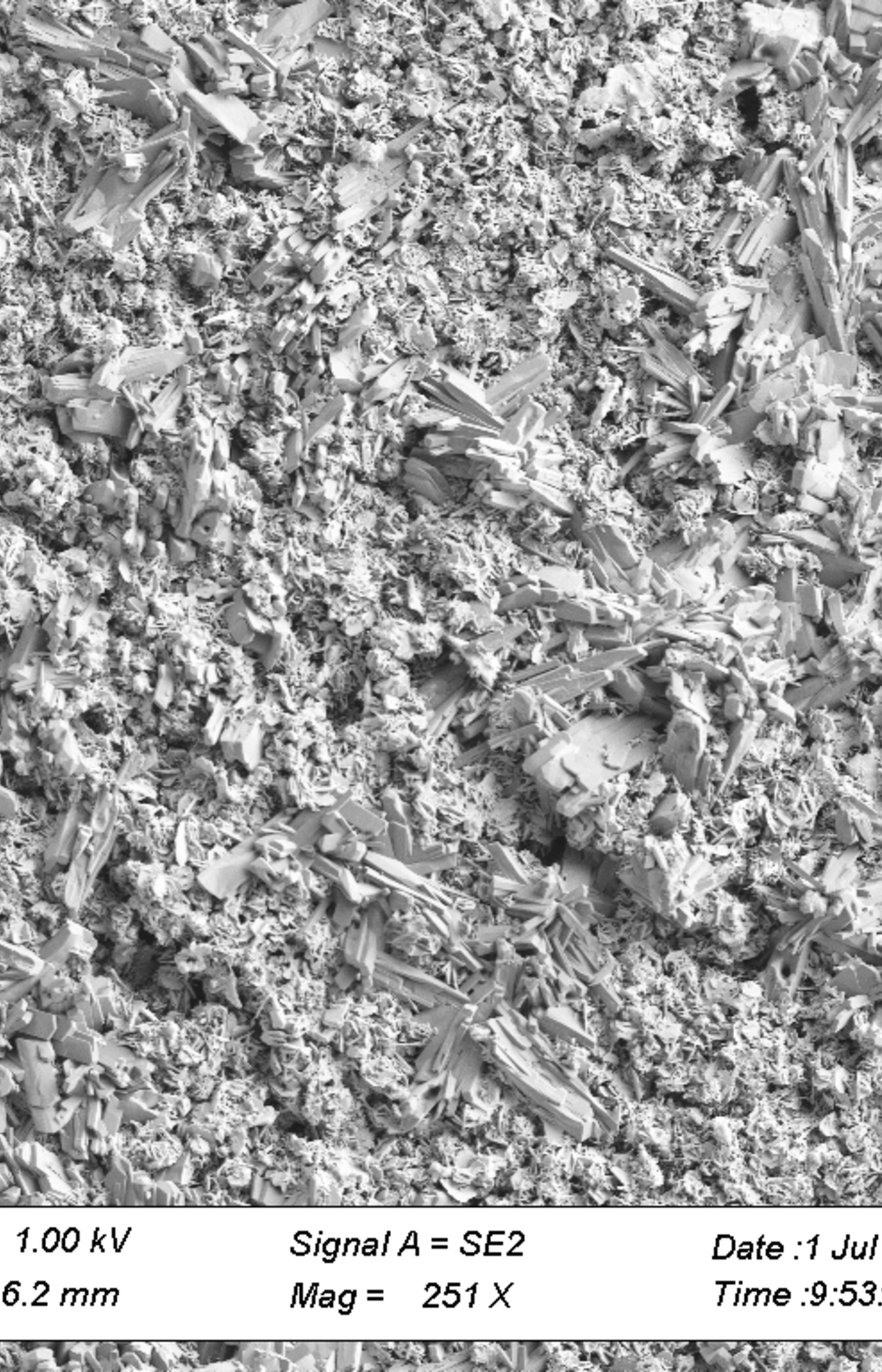

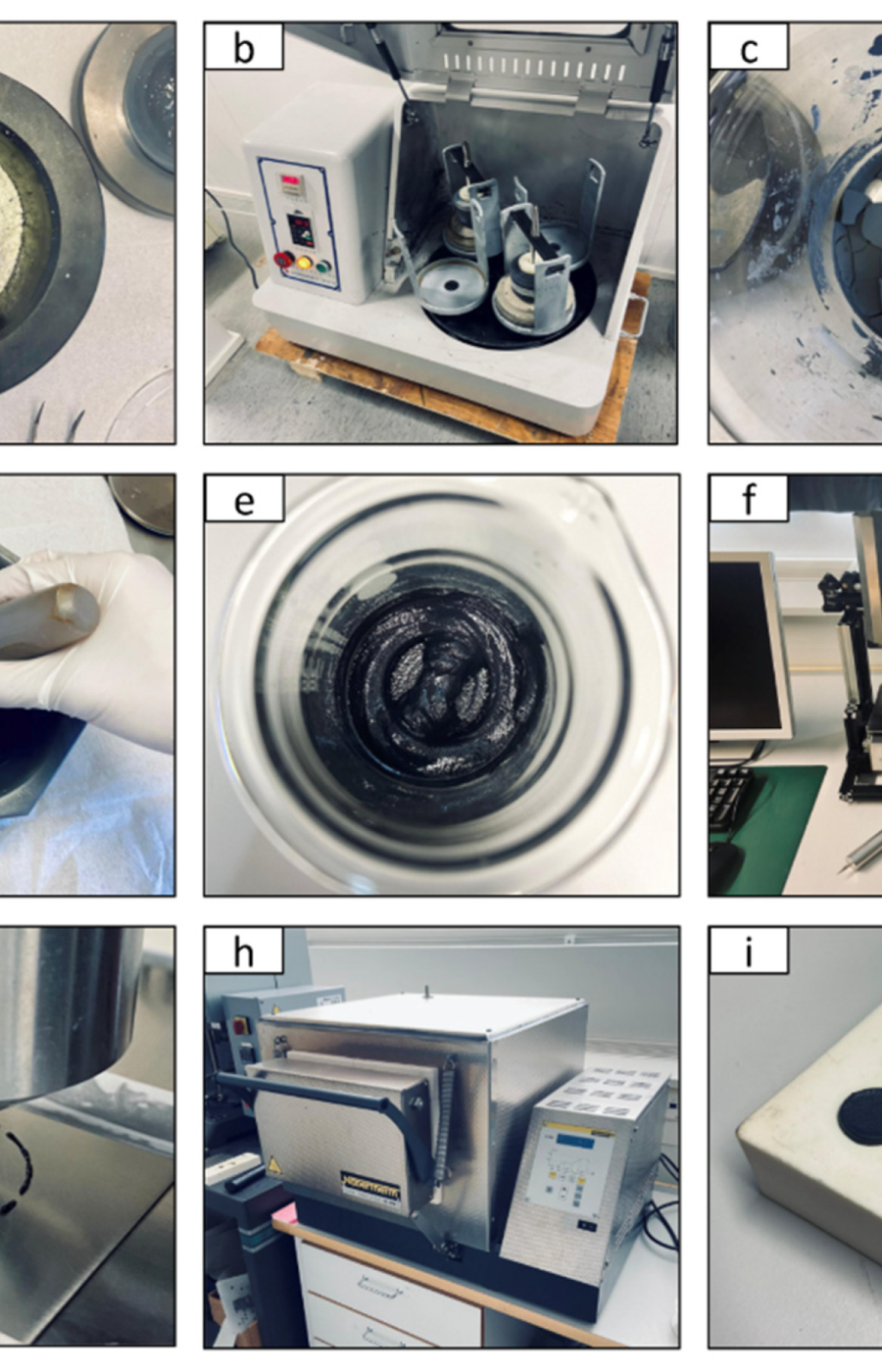

Researchers at Aalto University’s School of Science are investigating ways of improving the lifespan of fuel cells and cutting down the waste material generated in the manufacturing process. Fuel cells are typically manufactured by tape casting and screen-printing processes, but this creates toxic waste material that cannot be recycled. Aalto’s researchers are developing 3D and inkjet printing techniques to reduce this waste on an industrial manufacturing scale. They are also developing fabrication techniques that consume less critical earth metals.

3D and inkjet printing results are promising in terms of waste reduction; however, they are currently expensive to manufacture. This is where industry can step in to scale up production and lower costs, as has been the case with photovoltaic (PV9) solar panels. Until recently, solar panels were expensive to produce, but in the last decade the price of manufacture and purchase has fallen dramatically as production has scaled up.