ENICON (external link)

Sustainable processing of Europe's low-grade sulphidic and lateritic nickel/cobalt ores and tailings into battery-grade metals

Europe, and Finland in particular, are embracing renewable energy sources at a rapid pace. Metals such as nickel and cobalt are critical to building these renewable national energy infrastructures. Historically, these materials are intensely mined in a small number of countries, and there are economic, social, and political questions regarding importing materials from across the globe to Europe, and from countries with poor environmental and workplace regulations.

Mining in Europe is therefore urgently needed. While deposits are unevenly distributed globally, European ‘domestic’ production and processing of ores would go a long way to alleviating the current reliance on imports. The problem is that while many across the continent are enthusiastic about renewables, they are less excited by the thought of mines ‘in their backyard’.

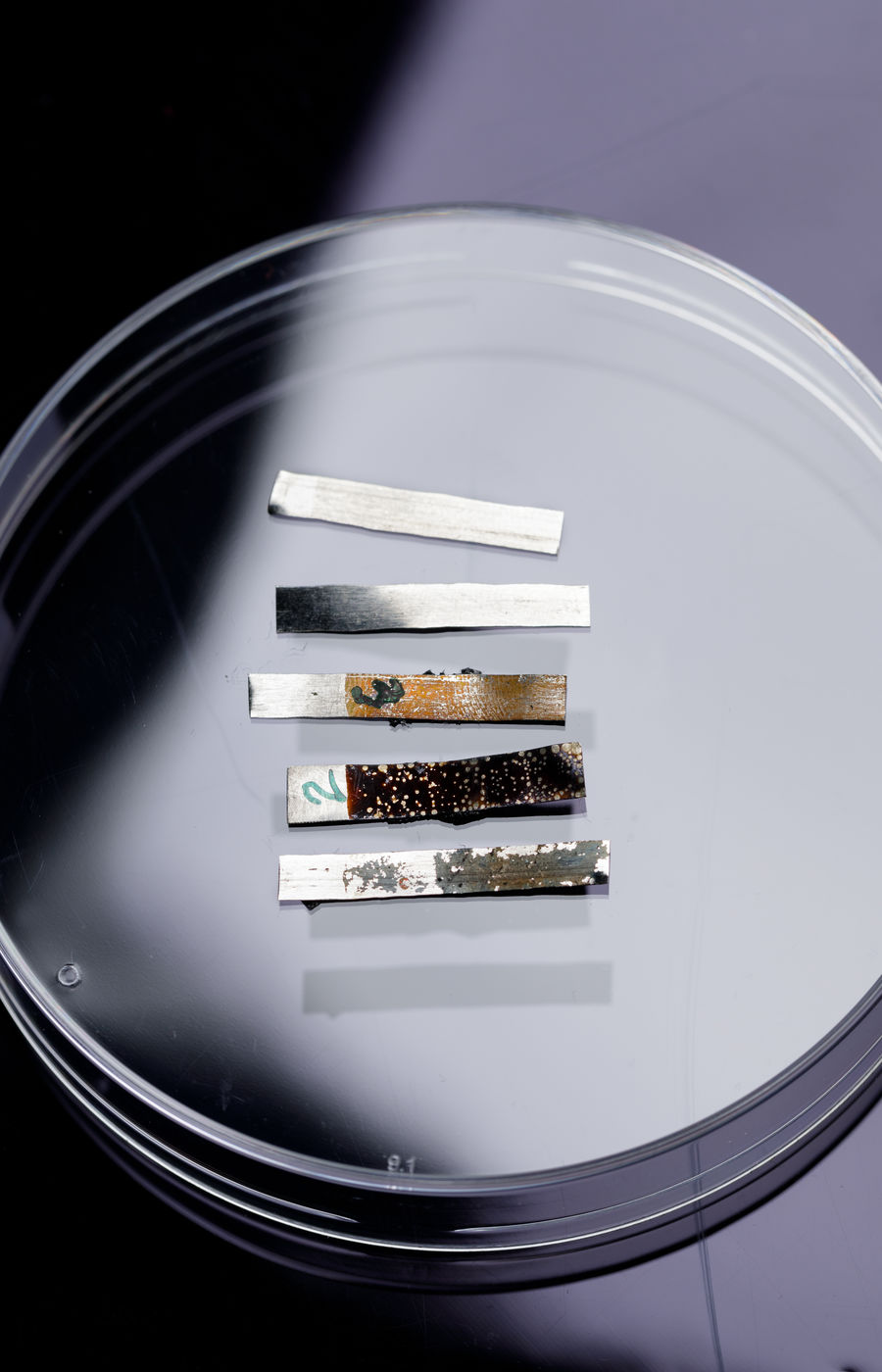

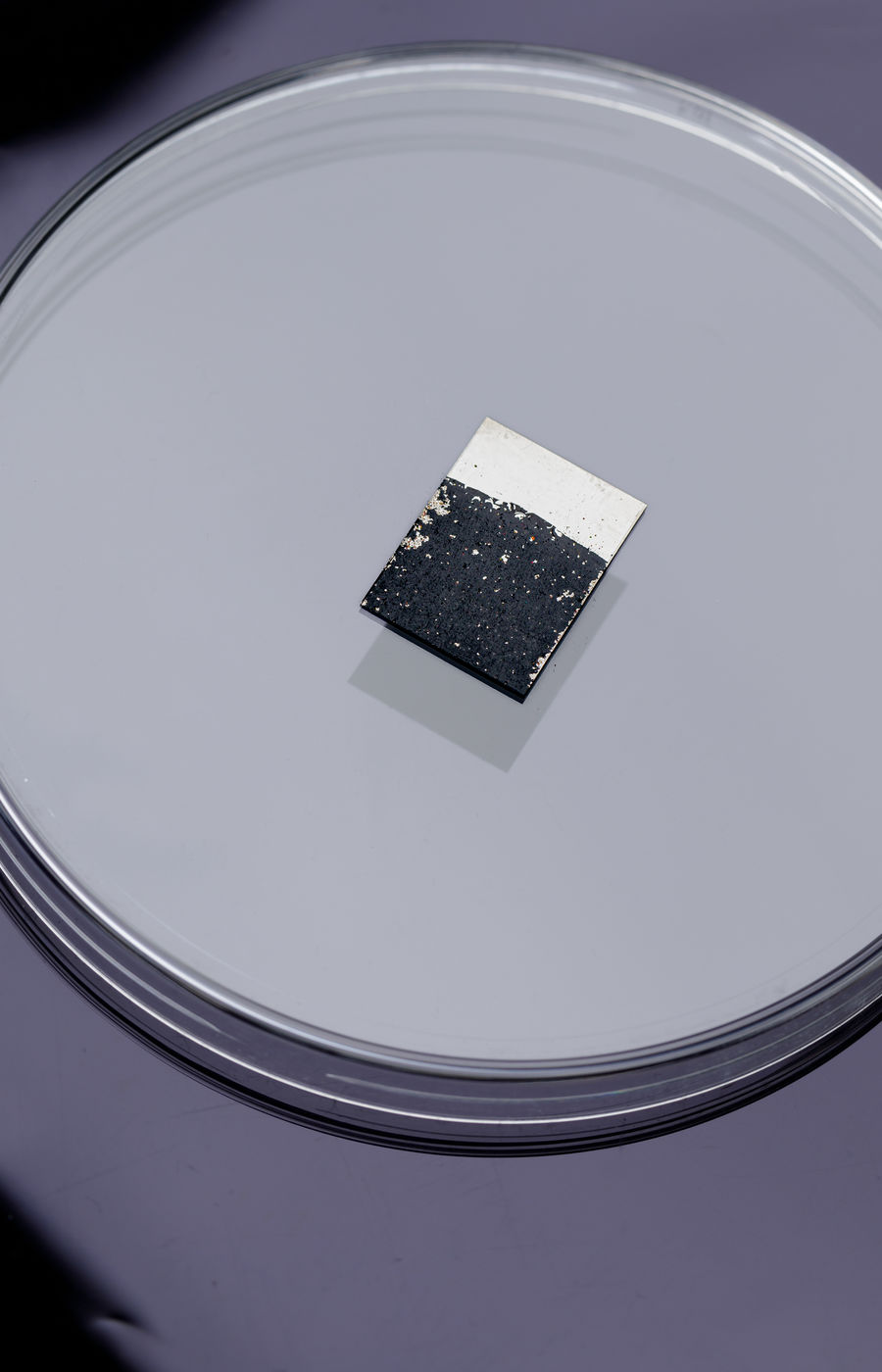

Aalto University is a partner in the ENiCoN consortium, a major academic and industrial project which looks to develop sustainable metal production practices in Europe, get the most out of the lower-grade materials, and repurpose waste materials. Researchers at Aalto’s School of Chemical Engineering are working on two spheres in ENiCoN – developing carbon-neutral metal production methods and studying novel ways of directly extracting cobalt and nickel out of process solutions using electricity.

Mining in Europe will impact nature and energy use patterns but is essential for our energy future. ENiCoN aims to minimise the environmental, biodiversity and societal impacts of mining by addressing each point of the chain. Mines would be electrified using renewable sources. Mining produces a lot of waste materials, known as tailings. ENiCoN researchers aim to utilise tailings using two methods. The first is to process tailings to further extract nickel and cobalt. The second is to repurpose spent tailings as construction material. Life after a mine’s expiry is also considered, by ensuring local safety by removing hazardous materials, thereby allowing mines to be repurposed, for example, by filling it with water to create a lake.

Fundamentally, the (re)use of critical metals prompt difficult societal decisions. A highly efficient battery innovation may emerge, but are there enough materials to deploy it nationwide? Driving an electric vehicle may emit less than a petrol or diesel equivalent, but if the electricity that charges your car comes from fossil fuel sources, is that an efficient use of the metals required for the car battery? Metal containing products will not last forever and can only be repurposed so many times. Considering the whole energy system is vital.

Researchers: Mari Lundström, Associate Professor, Hydrometallurgy and Corrosion and Ari Jokilaakso, Associate Professor, Metallurgy, Department of Chemical and Metallurgical Engineering, School of Chemical Engineering, Aalto University

Text: Peter Taggart

Sustainable processing of Europe's low-grade sulphidic and lateritic nickel/cobalt ores and tailings into battery-grade metals

Sustainable future with high performance products